We have a variety of vessel option to choose from our standard range. Beside the manufacturing of our Standard Vessels / Rectors, we specialize in producing reactors as per customer’s requirement. We can fabricate the reactor as per drawing or picture.

Our experiences team of Engineers can also assist in designing of glass reactor as per your requirement. Feel free to Contact us

Reactor Options: Single Wall, Double wall or Triple Wall Glass Reactor

One of the prime endeavor and proud moment for “GOEL Scientific Glass Works Ltd.” to

have designed lab glass reactor for the convenience of chemical scientists, R&D and Lab

fraternity, who make wonderful use of standard glass equipment to accomplish desired results and innovations.

“Lab Glass Reactor” has become very convenient, essential, and integral part of chemical

processing units to accomplish desired results which is a standard equipment Make in India.

Glass being an inert material is extremely useful for scientific fraternity with additional qualities of transparency, chemical resistance, and thermal stability.

Significant Features

Convenient Interchangeability – The lab glass reactor has a tool-free exchange system with a hose coupling quick-release reactor clamp. It also has a self-aligning stirrer coupling that engages without any tools.

Aesthetic Design

Lab Glass Reactor is most suitable for every chemical process unit. It is also ideal for all vacuum conditions due to its design and construction in SCHOTT Duran, GmbH glass with high-quality material at a reasonable price.

The triple stand support with stainless steel roads enhances the stability of the lab glass reactor.

Suitability

Lab glass reactor is most suitable requirement for every chemical process unit.

It is also ideal for all vacuum conditions due to its versatile design and quality material.

Why do we use 'SCHOTT Duran Glass ?

SCHOTT Duran meets a significant standards for technical glass such as ISO 3585:1998&ASTM

E438

Type 1. It’s a renowned glass for use, especially in scientific laboratories, architecture, and R&D

sector due to its versatility, resistance, strength, and availability in all dimensions worldwide

applications.

Technical Specification & Components of Lab Glass Reactor

1. 0.5 Ltr to 5 Ltr Double / Triple Wall Jacketed reactor with 100 DN / 150 DN Duran glass flange with groove – Made from Schott Duran Glass tubing

Primary Reactor – For Reaction

Double Wall Reactor – for Utility Circulation (-60°C to 200°C)

Tripple Wall Reactor – for Full Vacuum sealed Jacket to prevent energy loss &

to maintain transparency during condensation at -20°C.

2. Fused type bottom outlet valve with Screw thread operating

- Easy to open to clean

- minimum dead volume valve

- Contact parts PTFE

3. 100 DN/150 DN Duran Glass Flange cover with DURAN®

RODAVISS® Joints – Made from Schott Duran Glass tubing

4. 100 DN/150 DN “O” Ring Viton / PTFE/FFKM (Perfluoro elastomer)

5. SS304 Quick release heavy duty coupling with Graphite Filled Teflon material

- High compressive strength

- Improved wear resistance under load & permanent deformation

- Better thermal / electrical conductivity

- Good chemical resistance

- excellent frictional properties.

6. SS Magnetic Drive for Glass reactor

- Max. Working Pressure Full vacuum

- Max. Working Temp -60c to 200 c

7. SS316 with PTFE Lined stirrer 10 mm Rod

8. Pressure Equalizing funnel with DURAN® RODAVISS® Joints

9. High Efficiency 250 mm Long Double coil Condenser with

DURAN® RODAVISS® Joints

10. Unique Support system SS304 Scaffolding stand with Bakelite Knob with SS304 screw

- Medical Grade Bakelite

- Smooth & Glossy Finish

- Quick opening & easy lifting

- Universal Motor Mount

- Heavy-duty SS304 Base

1 RPM 50 to 1000

2. Motor Type – Brushless Dc

3. Torque 15 Ncm

4. Viscosity – 8000 Ncm

5. timer – 1 min to 99 Hr 59 min & infinity

6.Direction of rotation : Reversible CW/CCW

13.SS304 Insulated hose with Manifold Connection System with flexible movement

3/8″ x 750mm with Flanged Connection with Silicon Insulation / Nitrile Insulation

- Operating Conditions :

Temperature :– 70°C up to 180 °C

Pressure :Full vacuum up to 0.5 bar

Capacities :100 ml L up to 10 L

In addition to range of glassware, we also supply Benchtop Lab Glass Reactors. This includes small vessels (Double or Triple walled) from 0.5 L to 5 L. In addition we have all the glass components you are likely to need such as condensers,

receivers, addition funnels, reflux dividers etc.

Our Benchtop Lab Glass Reactors include easy accessibility through open support frame, manufactured from German

made Borosilicate glass and a minimal dead space with many other standard and optional features.

Key Specifications

Reactor Volume: 0.5 L to 5 L

Reactor Type: Double Walled & Triple Walled

Operating Pressure: Full Vacuum to 0.5 bar (g)

Gear Motor with Inbuilt Digital Indicator Speed Range 50 to 1000 RPM

Thermal Shock Resistance: (Dt): 60°C for Triple Walled and 110°C for Double Walled Reactors.

Standard GL Threads for Inlet and Outlet. (Inlet and Outlet can be supplied with beaded process pipe.)

Salient Features

• Glass Reactors made from Germany Raw Material.

• Lab Reactor system suitable for most benchtop fume hoods.

• Stirrer with suitable mechanical seal/stuffing box/magnetic seal.

• Skid Mounted and quick release clamp for easy installation & removable of glassware.

• Suitable for vacuum condition

• Flush bottom with minimum dead volume.

• Overhead Stirrer geared motor with built-in speed controller & display.

• Measurement Marking on the vessel.

• Interchangeable Stirrer anchor, propeller, turbine Digital temperature indicator

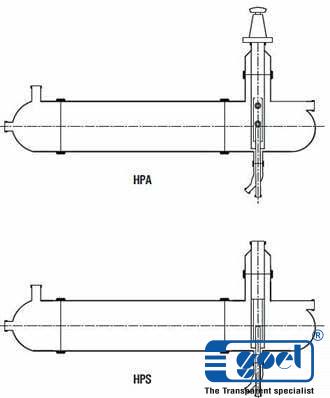

Reactors equipped with the flush bottom valve of the special type to ensure

leak-free sealing over entire temperature range.

All reactors are designed to keep L/ID Ratio within 1.5(max) for performance

and easy scale up. L/ID ratio may be changed on request.

All These Reactors are designed GMP.

Ideal for benchtop fume hoods.(SS/MS)

Stirrer with suitable seal (Mechanical, Stuffing Box, Magnetic Seal, High

Vacuum Stuffing Box).

Skid mounted and quick release coupling for ease of installation and

dismantling.

Overhead stirrer motor with built-in speed controller and display.

Interchangeable Stirrer (Anchor/Propeller/Turbine) as per your suitability.

Optional:Hot water/oil circulator, Chiller, heating /Cooling system ,Vacuum Pump, PH probe with transmitter, Pressure Gauge.