Bends

Borosilicate Glass Bends | Pipeline Glass Components Manufacturer

Product Overview

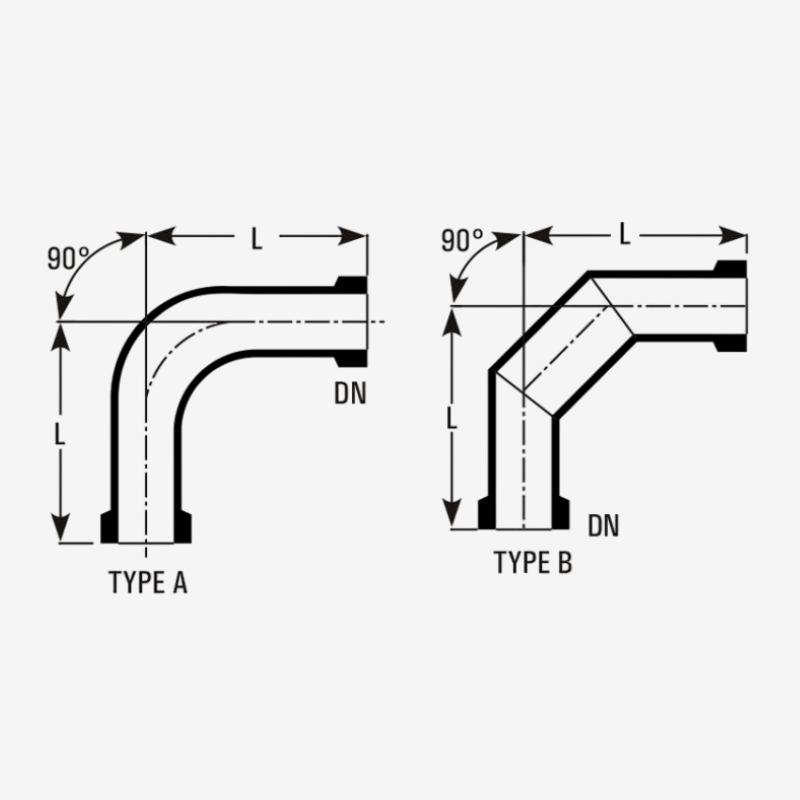

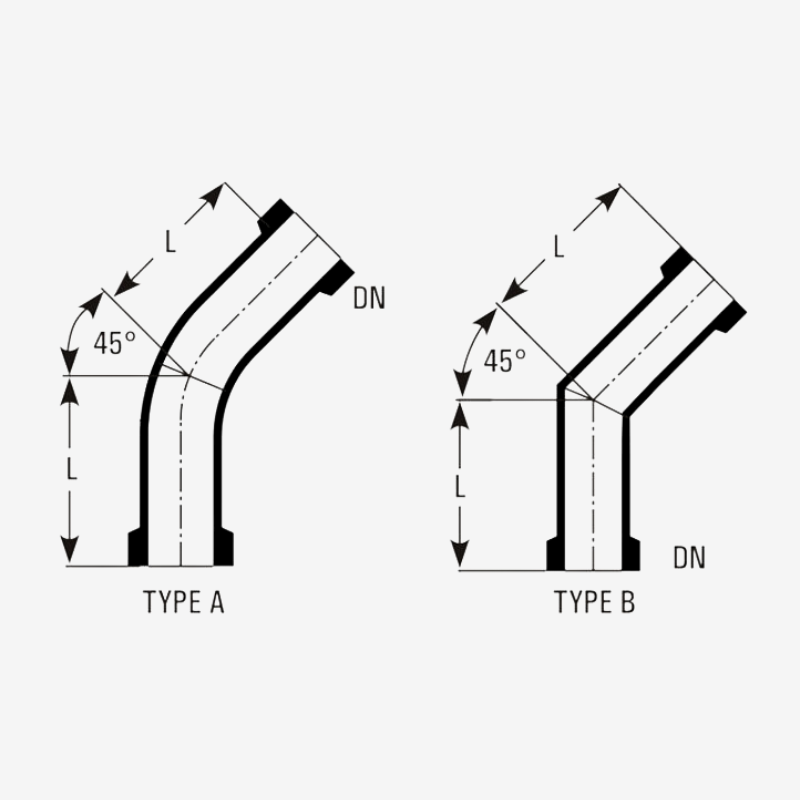

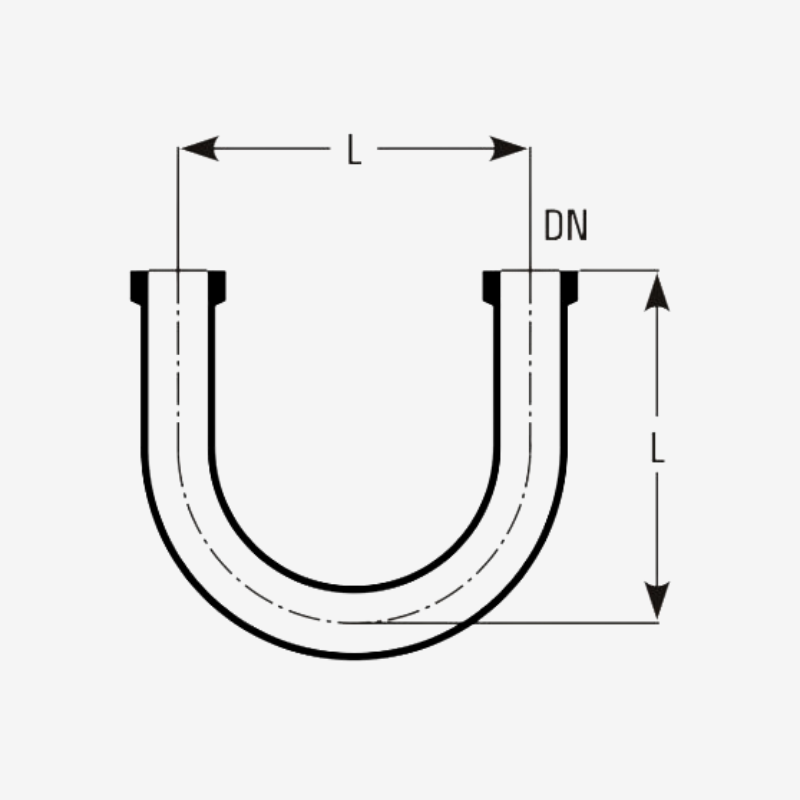

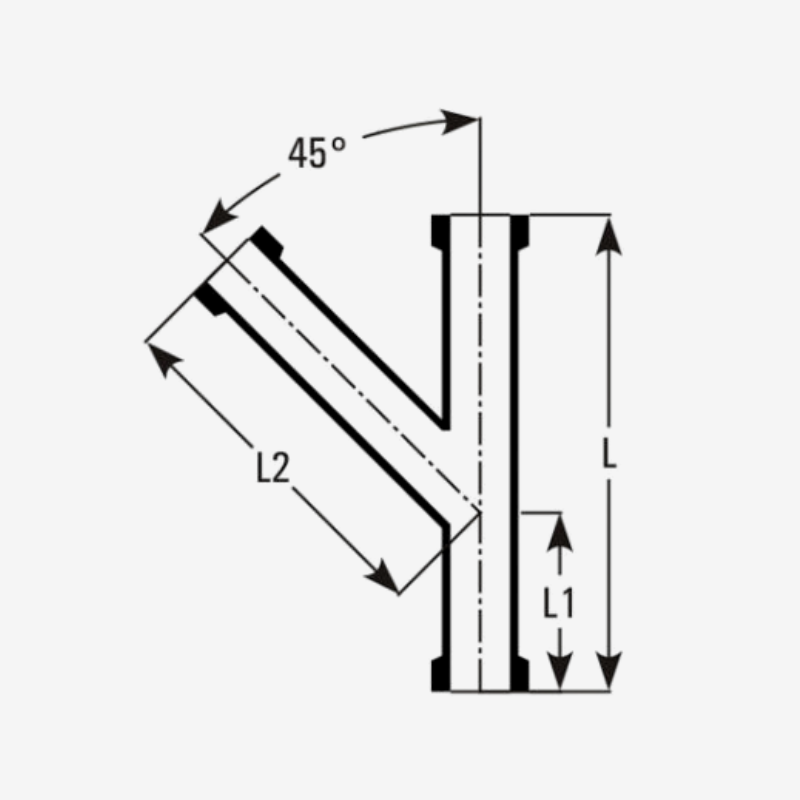

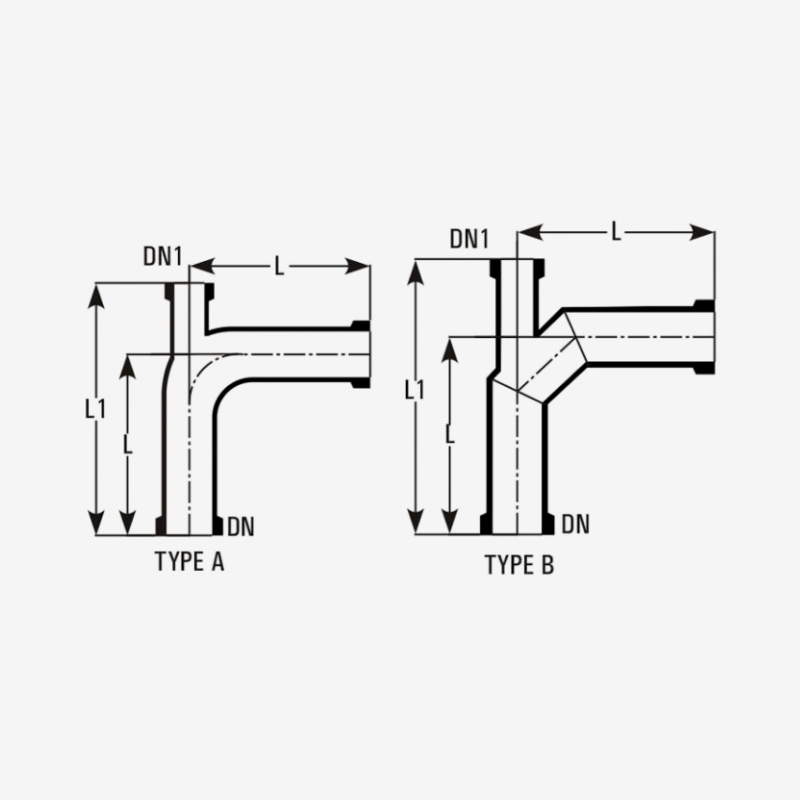

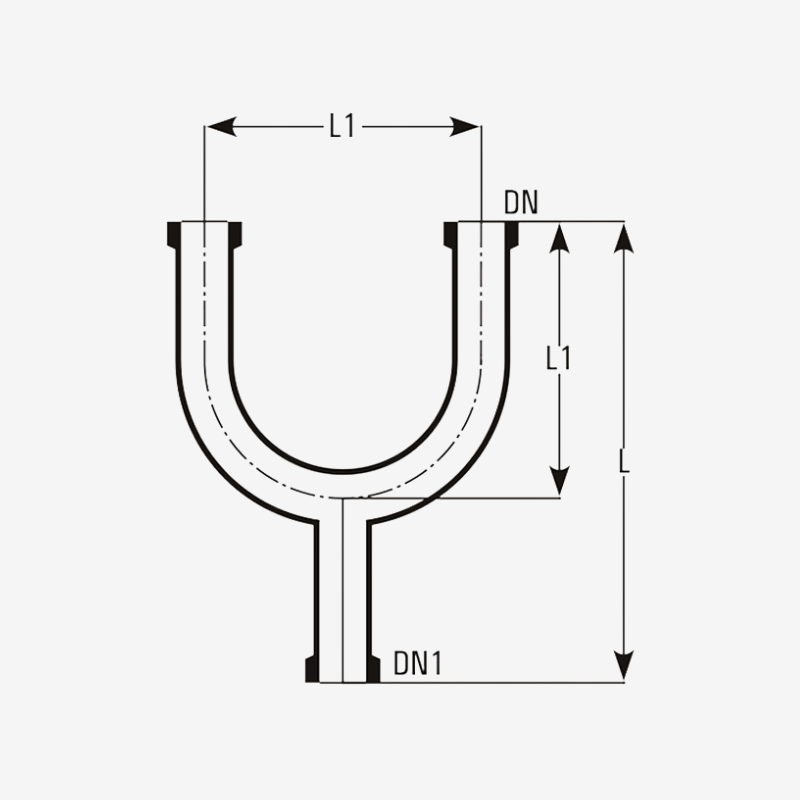

Goel’s glass pipeline bends are designed to direct fluid flow through angular paths while preserving transparency and chemical inertness. They manufacture various types, including BENDS 900, BENDS 450, U BENDS, Y BENDS, BENDS 900 With Thermometer Branch, U BENDS With Bottom Outlet bends, with catalogue reference codes such as PB, PU, PY, PBT, PUO, etc. These components integrate seamlessly into the general pipeline components line, maintaining vacuum compatibility and corrosion resistance.

Bends are essential pipeline components designed to change the direction of fluid flow in glass process systems. Manufactured from high-quality Borosilicate Glass 3.3, our bends ensure superior chemical resistance, thermal stability, and long service life in demanding industrial environments.