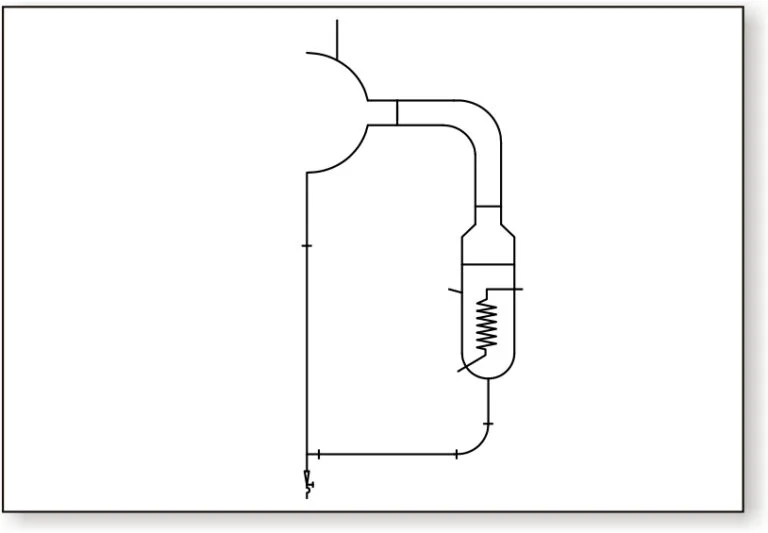

Boilers:

Designed for evaporation processes using steam through specially designed large cross-section coils.

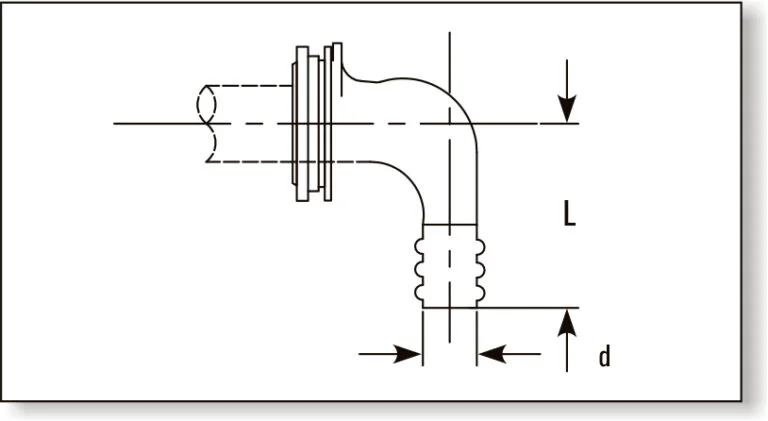

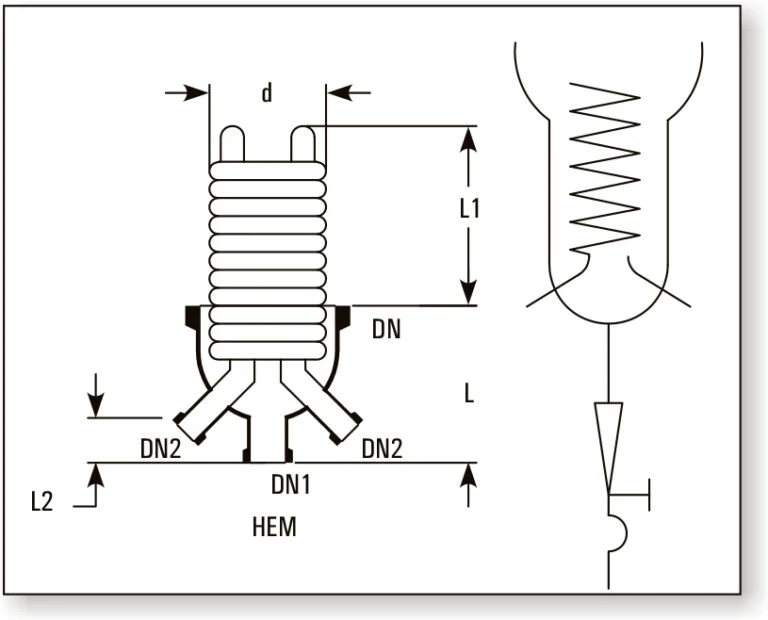

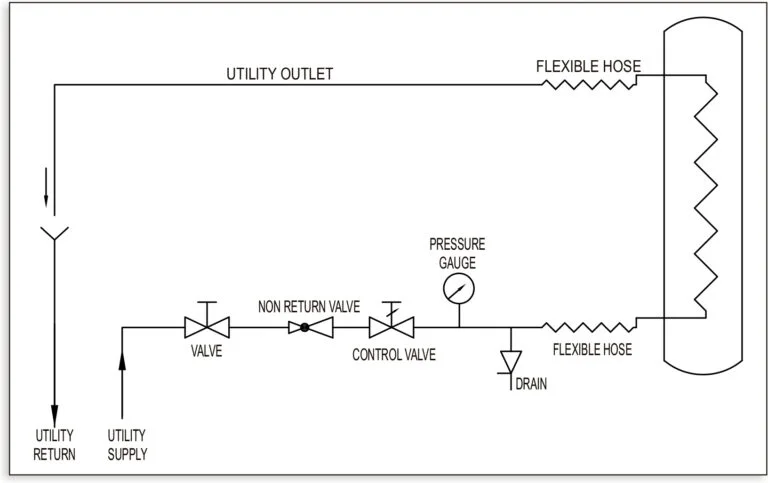

Immersion:

Used to control exothermic reactions in glass vessels (VSR & VSE types). Suitable for cooling water (max 2.7 bar g) or steam (max 3.5 bar g). Not recommended for crystallizing products.

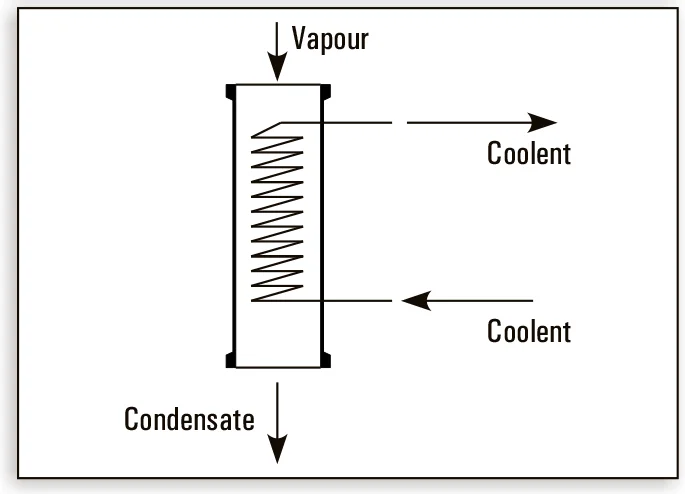

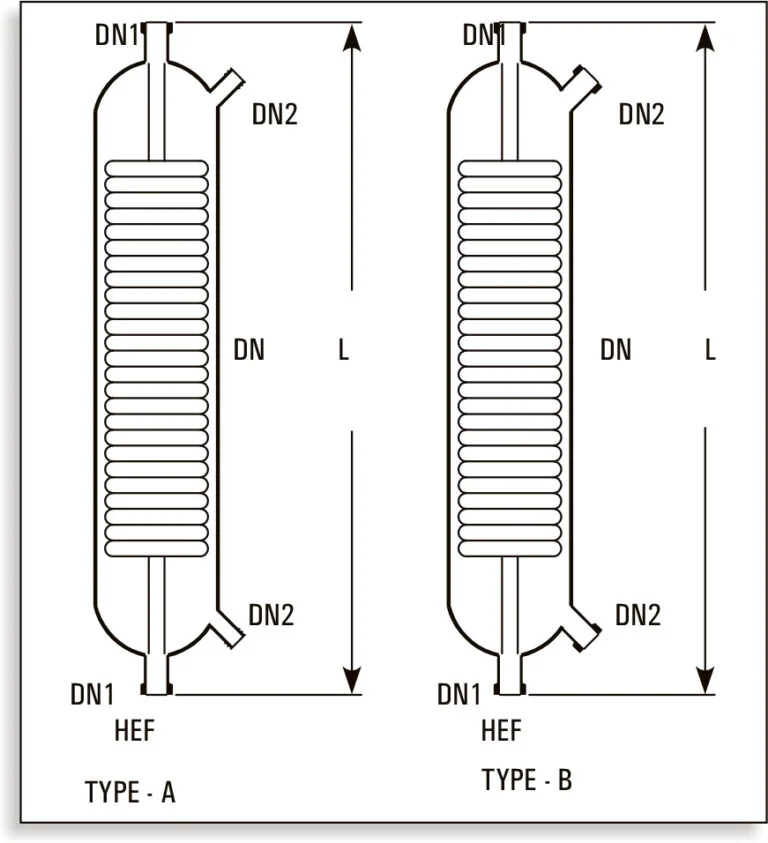

Product Coolers:Description:

Unlike coil condensers, product coolers allow the product to pass through the coil and coolant through the shell, offering extended residence time for effective cooling of distillates.