Description

Custom-Built Kilo Labs for Precision and Flexibility

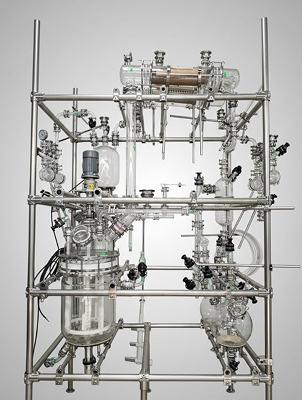

We design and supply customized Kilo Labs with intelligently positioned filling, sampling, and collection points to offer optimal control over every process stage. The transparency of our glass reactors provides a clear visual interface—allowing direct observation, data recording, and real-time analysis for process optimization and scale-up studies.

Comprehensive Distillation and Reaction Systems

Goel Scientific provides complete Kilo Lab assemblies integrated with Jacketed Glass Reactors and customized distillation units, which may include:

• Condensers and vapor columns

• Dean-Stark and reflux provisions

• Add-on and receiver vessels

• Phase separators and various valves

• Structural support frames in SS or coated steel Each system is compatible with a Thermal Control Unit (TCU) for precise temperature management. We also offer triple-wall glass reactors for enhanced thermal insulation and performance, available in working volumes up to 50 liters and beyond.