Liquid-Liquid Extraction Unit

Welcome to Goel Scientific Glass Works Ltd, your trusted partner in providing high-quality scientific glassware and equipment. We are proud to introduce our state-of-the-art Liquid-Liquid Extraction Unit, designed to meet the diverse needs of the chemical and pharmaceutical industries.

What is Liquid-Liquid Extraction?

Liquid-Liquid Extraction, also known as solvent extraction or partitioning, is a process used to separate two immiscible liquids based on their relative solubilities. It is an essential technique in various industries, including pharmaceuticals, petrochemicals, and environmental analysis.

Liquid extraction, also known as solvent extraction, is a widely used method for separating different components of a liquid solution. At Goel Scientific Glass Works Ltd, we offer a high-quality liquid-liquid extraction unit designed for semi-batch operations. This versatile unit allows for efficient extraction processes in various industries.

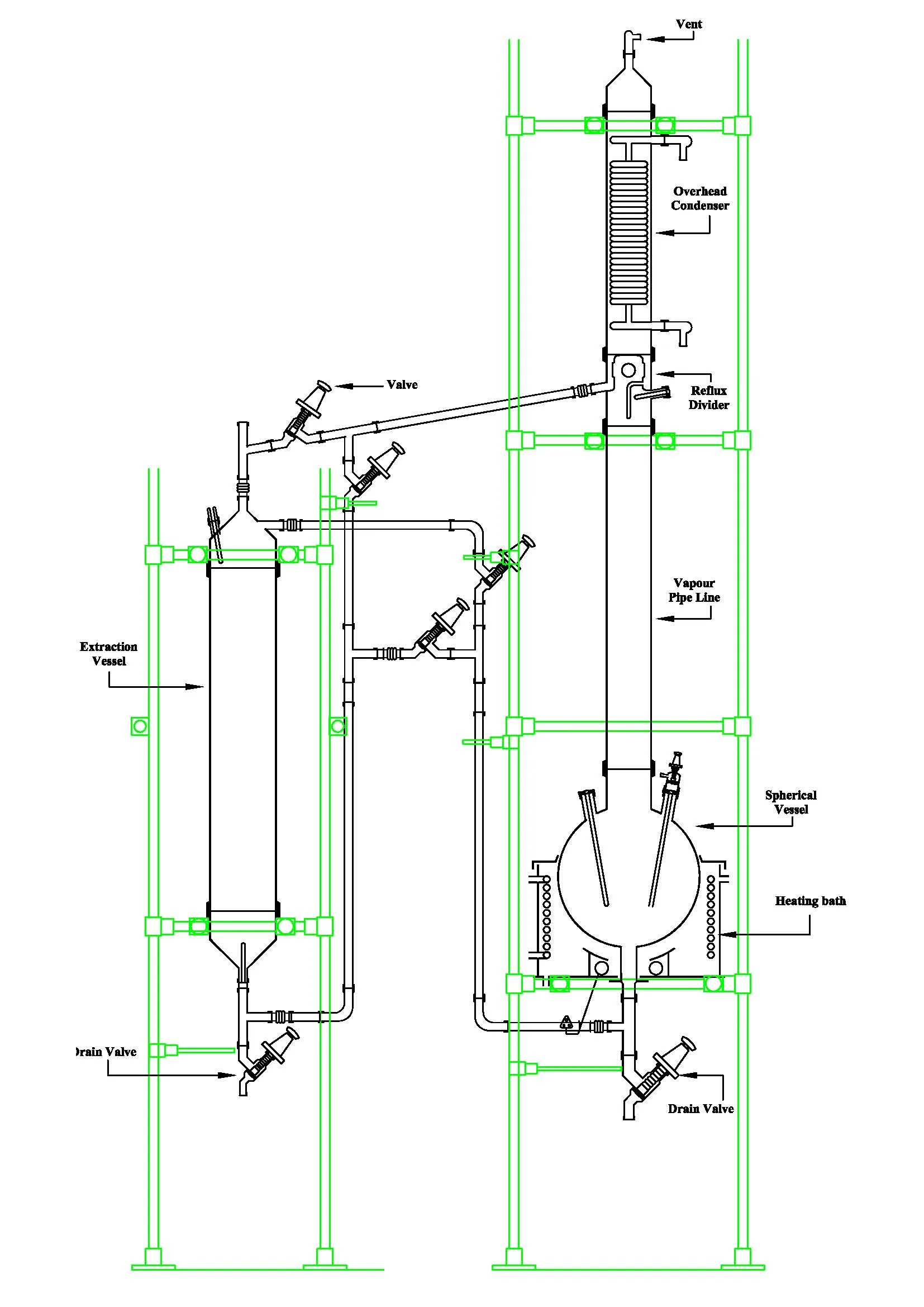

The liquid-liquid extraction unit consists of several key components. The process begins with the extraction vessel, where the liquid to be extracted is poured. Simultaneously, the solvent is boiled in a separate reboiler vessel and condensed in an overhead condenser. The condensed liquid then collects in a reflux divider and flows through pipework into the extraction vessel.

One of the unique features of our liquid-liquid extraction unit is the incorporation of valves in the pipework. These valves allow for precise control over the entry point of the solvent into the extraction vessel. Depending on the relative densities of the solvent and the liquid to be extracted, the solvent can enter either at the base or the top of the extraction vessel. This flexibility ensures optimal mixing and contact between the two liquids, enhancing the efficiency of the extraction process.

Once the extraction is complete, both the solvent and the extracted liquid are returned to the reboiler vessel. This continuous cycle of extraction and reboiling allows for multiple rounds of extraction, ensuring thorough separation of the desired components. The extraction vessel is then drained, and the solvent is evaporated from the reboiler vessel. The evaporated solvent collects in the extraction vessel, allowing for easy drainage of both liquids from their respective vessels.

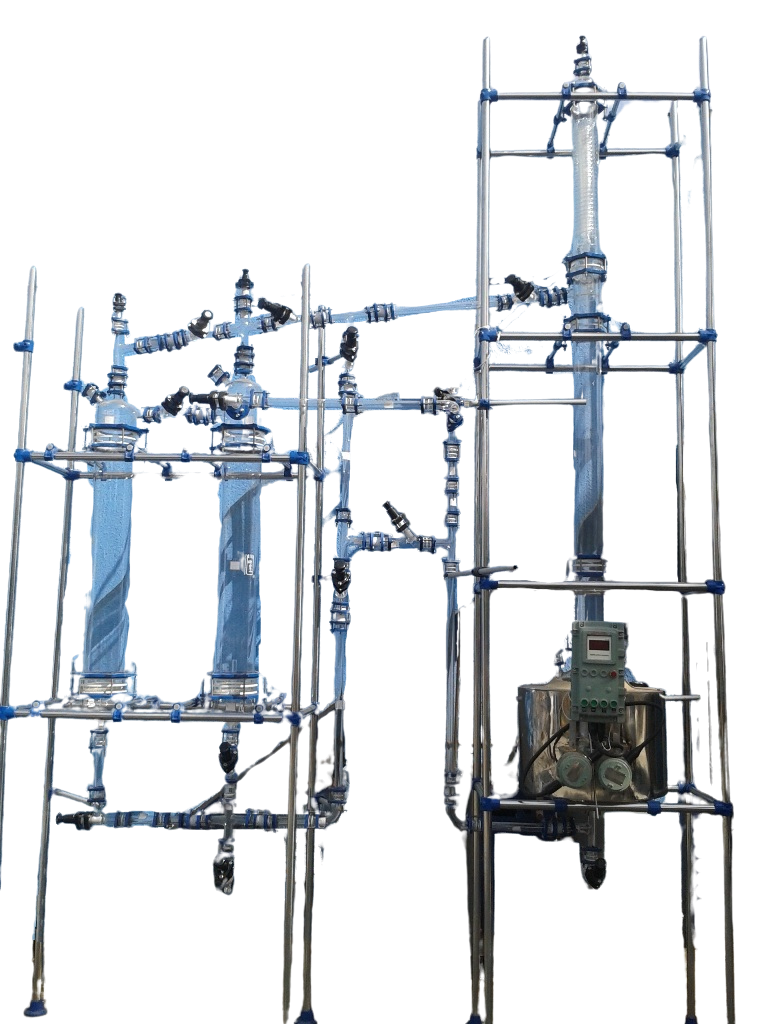

At Goel Scientific Glass Works Ltd, we offer liquid-liquid extraction units in various vessel sizes to suit different processing needs. Whether you require a smaller unit for laboratory-scale operations or a larger unit for industrial-scale production, we have the perfect solution for you. Our available vessel sizes include 20, 50, 100, and 200, providing options to meet a wide range of extraction requirements.

Our liquid-liquid extraction units are meticulously designed and manufactured to ensure durability, efficiency, and ease of use. We prioritize the quality of our products and employ the highest standards of craftsmanship in their production. With our extraction units, you can expect reliable performance, precise control, and excellent separation efficiency.

In addition to the exceptional quality of our liquid-liquid extraction units, we also offer comprehensive customer support. Our team of experts is always ready to assist you with any questions or concerns you may have. We understand that each extraction process is unique, and we are committed to providing tailored solutions to meet your specific requirements.

When it comes to liquid-liquid extraction, trust Goel Scientific Glass Works Ltd to deliver reliable and efficient equipment. Our liquid-liquid extraction units are designed to streamline your extraction processes and ensure optimal separation of components. With our commitment to quality and customer satisfaction, you can rely on us for all your extraction needs.

Contact us today to learn more about our liquid-liquid extraction units and how they can enhance your extraction processes. Let us be your partner in achieving efficient and effective separation in your industry.

Key Features of our Liquid-Liquid Extraction Unit

[embedyt] https://www.youtube.com/watch?v=lJda7EQSZEY[/embedyt]

Our Liquid-Liquid Extraction Unit offers a range of features that make it the ideal choice for your extraction needs:

- High Efficiency: Our unit is designed to ensure efficient mass transfer between the two liquid phases, resulting in higher yields and purity.

- Modular Design: The modular design allows for easy customization and scalability, ensuring that the unit can be tailored to your specific requirements.

- Temperature Control: Precise temperature control is essential for successful extraction. Our unit is equipped with advanced temperature control systems to maintain optimal operating conditions.

- Easy Operation: We understand the importance of user-friendly equipment. Our Liquid-Liquid Extraction Unit is designed with intuitive controls and clear instructions, making it easy to operate even for non-experts.

- Durable Construction: Built with high-quality materials, our unit is designed to withstand the rigors of industrial use, ensuring long-lasting performance and minimal maintenance.

Applications of Liquid-Liquid Extraction

The versatility of our Liquid-Liquid Extraction Unit allows it to be used in a wide range of applications:

- Pharmaceutical Industry: Liquid-Liquid Extraction is commonly used in the pharmaceutical industry for the purification and separation of active pharmaceutical ingredients (APIs) from complex mixtures.

- Petrochemical Industry: The extraction of valuable compounds from crude oil and petroleum products is a critical step in the petrochemical industry. Our unit offers efficient extraction solutions for this application.

- Environmental Analysis: Liquid-Liquid Extraction plays a crucial role in environmental analysis, allowing for the extraction and concentration of pollutants from water and soil samples.

- Food and Beverage Industry: The extraction of flavors, fragrances, and natural compounds from plant materials is an important process in the food and beverage industry. Our unit provides reliable and efficient extraction capabilities for this purpose.

Why Choose Goel Scientific Glass Works Ltd?

At Goel Scientific Glass Works Ltd, we are committed to providing our customers with the highest quality scientific glassware and equipment. When you choose our Liquid-Liquid Extraction Unit, you can expect:

- Quality Assurance: Our unit is manufactured using the finest materials and undergoes rigorous quality control to ensure reliable performance and durability.

- Technical Support: We have a team of experienced professionals who are ready to provide technical assistance and guidance throughout the installation and operation of our Liquid-Liquid Extraction Unit.

- Customization: We understand that every application is unique. Our unit can be customized to meet your specific requirements, ensuring optimal performance and efficiency.

- Competitive Pricing: We offer our Liquid-Liquid Extraction Unit at competitive prices without compromising on quality, making it an excellent investment for your business.

- Global Reach: With our extensive network of distributors, we can deliver our products to customers worldwide, ensuring timely and efficient service.

Contact Us

If you are interested in our Liquid-Liquid Extraction Unit or have any inquiries, please feel free to contact our dedicated sales team. We will be happy to assist you and provide you with all the information you need to make an informed decision.

At Goel Scientific Glass Works Ltd, we are committed to excellence and look forward to serving you with our top-of-the-line Liquid-Liquid Extraction Unit.