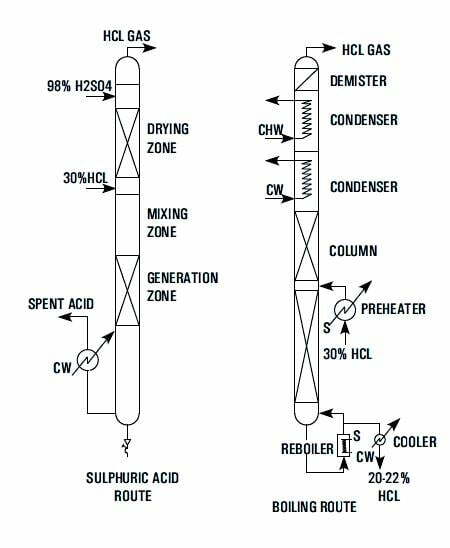

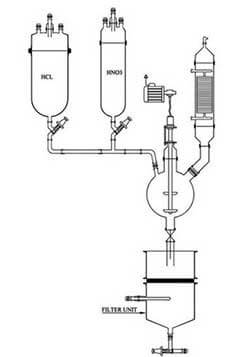

The process to purify industrial/technical grade nitric acid involves a single stage distillation to leave non- volatile impurities in the still bottoms.

69% – 70% concentrated nitric fluid is delivered by means of a metering pump from a storage tank into the glass still which is equipped with Electrically heated Oil Bath.

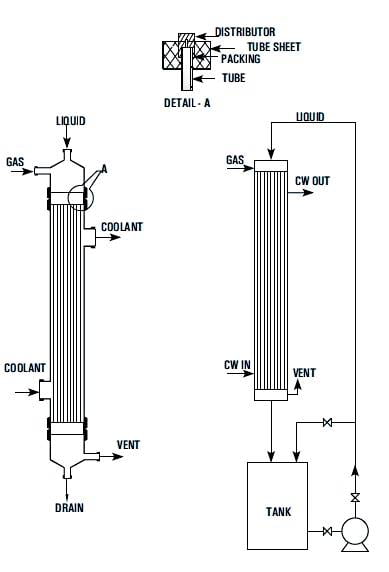

The acid vapors flow through a mist removing packed section to the Glass condenser. Depending on the desired concentration high pure water can be added as a diluent to the condensed product before entering the bleach column.

Clean air is introduced at the base of the bleacher. Air and oxides of nitrogen are vented through a condenser to a scrubber.

Entrained nitric acid is not returned to the bleaching column but collected separately. Removing of all NOx out of electronic grade nitric acid.

Design Basis & Requirement of Utilities :

| Capacity | 40 | kg/hr |

| Commercial grade Nitric Acid – 69-70% | 44 | kg/hr |

| Electric Heater | 48 | kw |

| Cooling Water @ 7 deg. C* | 4-5 | Cu.M/hr |

| Space Requirement | 3 x 3 x 8 m |

Size Available 5 kg/hr to 500 kg/hr