Heat-sensitive products like vitamins, hormones, enzymes or aromatic substances get adversely affected by way of material degradation due to higher temperature and residence time. This can be avoided if the reactions are carried under a vacuum which allows the working temperature to be lowered, and by forming a thin film to reduce residence time, especially in case of liquids of high viscosity, or low thermal conductivity.

For these, GOEL introduces a specially designed range of Evaporators made of Borosilicate Glass. The range varies from laboratory size (80DN) to production plants (300DN).

Wiping Film Evaporator | Falling Film Absorber

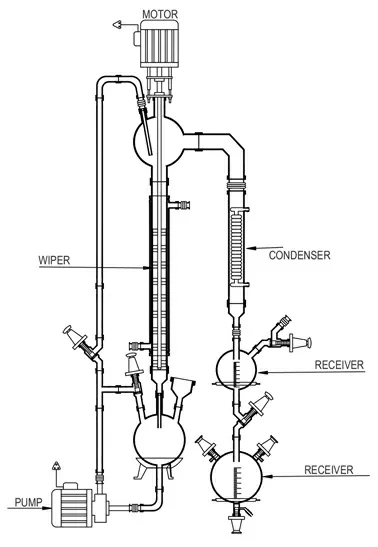

Construction

The core of the unit is a rotating, fully corrosion resistant wiper system. This has four rows of PTFE wipers. These rows of wipers are divided into vertical segments and each wiper is mounted between two glass rods.

A liquid distributor is located above the wipers. It distributes the medium, fed in through the feed pipe uniformly around the circumference of the evaporator before the medium is finally picked up by the wiper system itself.

The Evaporator has a vapour outlet which can be connected to a descending coil condenser and a receiver.

The drive used for the wiper system is a standard geared motor with an AC speed regulator. The wiper shaft is sealed by means of a mechanical seal. The evaporator body is constructed as a jacketed pipe. For heating, thermic fluid up to 150 C can be circulated in the jacket.

The unit is designated by the jacketed pipe size. And the capacity of the unit depends on the evaporation rate which in turn depends on the HTA available, the type of heating media, and the evaporation environment i.e. vacuum conditions.

| MODEL | SIZE DN (MM) | HTA(M2) |

|---|---|---|

| WFE3 | 80 | 0.35 |

| WFE4 | 100 | 0.47 |

| WFE6 | 150 | 0.70 |

| WFE9 | 225 | 1.06 |

| WFE12 | 300 | 1.41 |