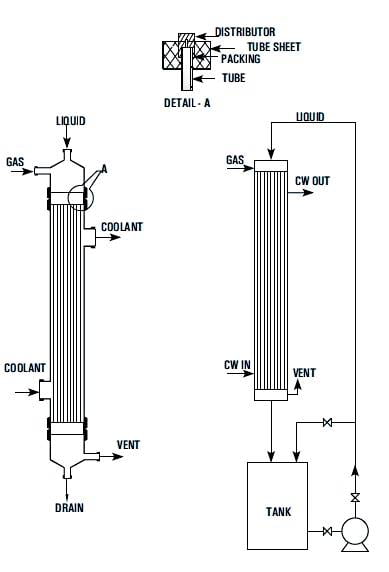

Falling film Absorber Goel Scientific Glass Works Ltd

Efficient gas absorption depends on the following:

1. Intimate contact

2. Efficient Heat Transfer

This is achieved in a Falling Film Absorber which is essentially a shell & tube heat exchanger in which both gas to be absorbed and absorbing liquid flow co-currently downward with the extraction of heat by circulation of coolant in the shell.

The absorbing liquid is circulated through a tank till desired concentration is achieved. The liquid flows at such a rate that the tubes do not flow full of the liquid but instead, descend by gravity along the inner walls of the tubes as a thin film.

Obviously, this produces a much greater linear velocity for a giver rate flow than could be obtained if the tube flowed full.

The equipment works as a number of water-cooled-wall columns in parallel and each tube is provided with a distribution system on top to effect uniform distribution of both liquid and gas and also the formation of a thin liquid film on the inner surface of the tube.

| Sr. No. | Nominal Size (mm) | Absorber Area (m2) | No. Of Tubes/Tube OD (mm) | Max. Gas Absorption Rate (Pure HCL)* (Kg/hr) | Max. Acid Prod. Rate (As 30% HCL)( Kg/hr) | Height (m) |

| 1 | 80 | 1.00 | 4/20 | 30 | 100 | 4400 |

| 2 | 10L | 20L | 40 | 10 | 20 | 40 |

| 2 | 100 | 1.76 | 7/20 | 60 | 200 | 4500 |

| 3 | 150 | 4.80 | 19/20 | 150 | 500 | 4600 |

| 4 | 225 | 7.80 | 31/20 | 250 | 833 | 4920 |

| 5 | 300 | 15.30 | 61/20 | 500 | 1667 | 5050 |

| 6 | 400 | 36.00 | 143/2 | 1175 | 3917 | 5300 |

| 7 | 450 | 47.00 | 187/20 | 1500 | 5000 | 5700 |

| 8 | 600 | 84.00 | 333/20 | 2700 | 9000 | 5800 |